This is the first in a series of articles looking at illumination in a little more depth. Lighting i

This type of specialist illumination is very sophisticated, requiring the application of science to understand why and how different lighting options are suited to different uses.

Begin at the beginning with illumination

Before you even start to look at the lighting options available, there are several considerations to take into account when planning a particular job:

- Monochrome or colour?

- High-speed or low-speed application?

- Service life of the light?

- Size of area to be illuminated

- Nature of the object in question (geometry, reflectivity, etc.)

- Feature of interest?

- Surrounding environment: what are the constraints?

Now you’ve got an idea of what you need, here’s a look at the type of lighting available…

LED (light-emitting diode)

LEDs are a semiconductor light source used as indicator lamps in a variety of devices – and increasingly for other types of lighting, including vision systems.

Modern LEDs are extremely versatile, producing light right across the visible, ultraviolet and infrared wavelengths. They work by recombining electrons with electron holes within the device, releasing energy as photons. This is the electroluminescence effect, and the colour of the light produced corresponds to the energy of the photon, which is determined by the energy gap of the semiconductor.

Modern LEDs are extremely versatile, producing light right across the visible, ultraviolet and infrared wavelengths. They work by recombining electrons with electron holes within the device, releasing energy as photons. This is the electroluminescence effect, and the colour of the light produced corresponds to the energy of the photon, which is determined by the energy gap of the semiconductor.

Advantages of LEDs over incandescent light sources include:

- Lower energy consumption

- Longer lifetime

- Improved physical robustness

- Smaller size

- Faster switching

Because white LED light is created using phosphorescent and fluorescent materials to re-emit part of the light in a wider spectrum, it has a high colour temperature. This makes LED light particularly suitable for colour vision applications, where colour accuracy is important.

We can control several factors affecting performance, efficiency and life of an LED lighting system:

- Wavelength and filtering

- Diode efficacy

- Timing and strobing

- Thermal management

We’ll go into a bit more detail about these factors in a future blog.

Laser lighting

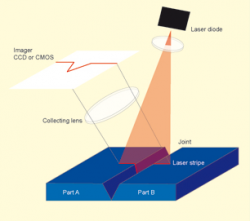

Laser diodes work using the same materials as LEDs, but are built to a higher tolerance. Their additional structures ensure that light output is a focused beam rather than a broad-band incoherent light source.

Laser diodes work using the same materials as LEDs, but are built to a higher tolerance. Their additional structures ensure that light output is a focused beam rather than a broad-band incoherent light source.

The wavelength is susceptible to change depending on the temperature of the unit: the entire diode structure can alter when heated, either by the laser diode itself or from some external heat source. So temperature control in the surrounding environment is important when creating a laser-illuminated vision system.

Lines and 2D patterns are very useful for machine vision applications involving precise non-contact measurement. We’ll go into this in more detail in a future blog.

Incandescent lighting

These are “traditional” light bulbs consisting of a glass envelope that contains a vacuum or low-pressure noble gas such as argon. Light is produced by passing an electric current through a filament wire (usually of tungsten), heating it until it glows.

These are “traditional” light bulbs consisting of a glass envelope that contains a vacuum or low-pressure noble gas such as argon. Light is produced by passing an electric current through a filament wire (usually of tungsten), heating it until it glows.

They are rather inefficient, partly due to the extremely high temperatures the filament is heated to (typically 2,000K – 6,000K).

Incandescent illumination is seldom used for vision systems, partly due to their inefficiency, but also because of their instability and AC fluctuation.

Other types of illumination

Halogen has a high-intensity light output, but has a short unit life and an inflexible design.

Fluorescent lighting is used in some situations, but has very limited use in industrial vision environments. They are unstable and cannot be easily intensity controlled or strobed.

Stay tuned for more information on light sources and lighting techniques – as well as applications and methods!