In days of yore, someone would take a couple of items per hour off a production line and measure the

An increasing focus on quality means that more and more products need to be tested – and a dozen people all measuring a variety of stuff manually is not the way to go about it.

Non-contact measurement is much faster and doesn’t interrupt the items rattling past on a conveyor belt. We do this with cameras, which measure every single item that whizzes past without disturbing or removing them from the line.

Non-contact measurement is much faster and doesn’t interrupt the items rattling past on a conveyor belt. We do this with cameras, which measure every single item that whizzes past without disturbing or removing them from the line.

As well as saving time and effort, and ultimately money, this also means that the products are handled less. For fragile items this is vital: there is less handling damage, fewer fingerprints and scratches.

Give me an example

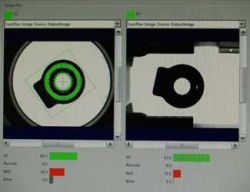

Often we are verifying that a component is in place, that the lid is on, that all the components are present. Other times it is the relationship between these components that is the important factor. Think about the gap on a spark plug: if it’s too small, the fuel won’t detonate as cleanly as it should. If the gap is too large, the fuel might not detonate at all.

The gap will have very tight manufacturing tolerances, and checking them all manually is both slow and expensive. That’s a perfect example of non-contact measuring that is ideally suited for a non-contact measurement vision system.

So, how does it work?

At Bytronic, we use industry-leading technologies, years of experience and our technical know-how to put together a system that will do just what our clients need. Whether it’s detecting presence or absence, things that need measuring, codes that need reading, fill levels that need checking, or assembly that needs verifying, a system can be built to achieve it.

By physically arranging the items carefully, a consistent image is achieved from each (removing the problem that “this cow is small, and this cow is far away”). In other words, we ensure that each item is at a known distance from the camera.

Telecentric lenses (more on those at a later date) keep object images at a consistent size regardless of their distance from the camera (within fixed parameters). This can lead to some strange-looking images, but for the purposes of measurement, they’re perfect.

With software calibrated so that measurements are in real-world units rather than pixels – so the numbers that are measured are useful in the real world.

Get in touch with us if you’d like to find out more!