We often undertake free trials for prospective customers, to enable us to provide an accurate quote

Recently, we were approached by a supplier to a printer manufacturer to find out if it were possible to check for blocked or defective inkjets.

So, being curious and obliging chaps, we gathered together some equipment and got stuck in.

The problem

At the moment, inspection of the test print is done manually – which is slow, expensive, and prone to mistakes. The client wants to determine if it’s possible to undertake production-line testing of printer inkjet heads at the time of manufacture, to check for blocked or defective inkjets.

After the manufacturing process, the printer head is connected to a test station and prints a test pattern. Each jet is required to print one segment of the pattern.

The specifications

For this trial, we used the Cognex InSight 7402 camera with ‘cloudy day lighting’. This is white light, evenly spread to provide uniform lighting and is achievable using diffuse backlights or a dome light.

We may find, when we come to put the vision testing system together in-situ, that there is a more appropriate combination of cameras and lighting. In fact, it is likely that different specifications will be used, as the lighting and available space will be different in the factory setting.

Our trial

With the ‘cloudy day lighting’ providing a nice, uniform illumination, we set up the camera so that it was looking at a sheet of paper. The paper had a test pattern printed onto it by the inkjet head that was undergoing the test.

The camera looks at the test pattern and undertakes the following:

- Checks where the pattern is (there may be a bit of movement from one test to the next)

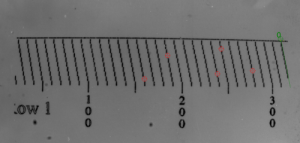

- Finds the 30 or so printed lines, each of which have 10 segments (from 300 jets in total)

- Checks each line for missing segments

- Performs checks to spot blank areas, informing the test cell that there is a blocked jet(s)

- Information is sent via digital I/O (input/output), Ethernet or ftp if more data capture is required.

Following these checks, the test cell accepts or rejects the print head. Depending on the test result, the printer head is assembled into a printer, or discarded.

What’s next?

The trial was a success: our vision system performed as desired. After a few tweaks and alterations, it was catching all the blank areas without giving us any false positives.

If the system is installed onto the production line, the set-up will be altered to fit in with the existing system, and it is unlikely that the cameras will be looking at a flat sheet of paper – so there will be more experimentation to be done in the future! Watch this space…