Ensure product stability and sustainability with HotSpot automated quality control

HotSpot is a fully automated thermal vision inspection system that eliminates defects in packaging and avoids expensive product recalls. HotSpot stops faulty packaging in its tracks. Make plastic wrap a thing of the past by guaranteeing your cardboard or paperboard packaging is strong, safe, and sturdy.

This fully automated quality control inspection system accurately and instantly checks hotmelt glue adhesive across a wide variety of packaging types. HotSpot helps industries phase out single-use plastics and can be retrofitted to existing packaging lines.

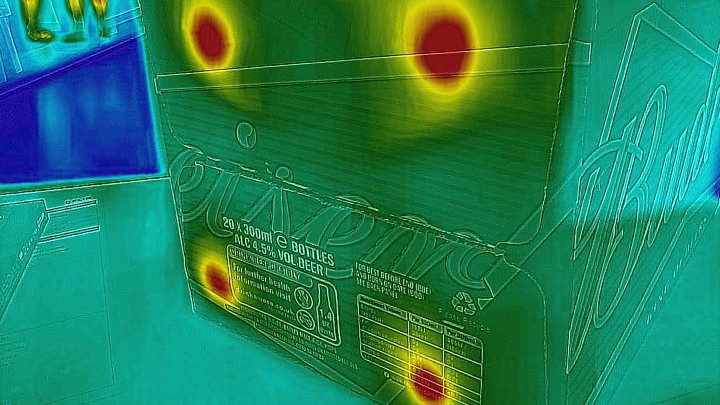

Combining FLIR thermal cameras with Cognex Vision Pro software, HotSpot can monitor the shape, size, location, and temperature of hotmelt glue application to ensure packaging is correctly formed and sealed.

Automated inspection for hot-melt glue packaging lines

100% in-line inspection

Ensure 100% inspection of every product at speeds of up to 60 packs per minute. Prevent costly recalls, save operational time and automate manual inspections.

Reduce costs and recalls

Accurately ensure product packaging is safe and reliable before it leaves the factory, reducing the risk of recalls and reputational damage.

Hit sustainability targets

HotSpot automated vision inspection and monitoring can help to remove plastic from production lines and reduce the need for excess packaging.

Prevent collapsing multipacks and ensure pallet stability

HotSpot™ is used by Budweiser, Stella Artois, Brahma, Corona and Heineken to package millions of bottles and cans per year.

- Can be installed or retrofitted to any conveyor or cartoning machine

- Can be fitted and set up in under two hours, with professional installation as an option

- FLIR longwave infrared thermal cameras, Cognex Vision Pro software and touchscreen control panel included as standard

- Compatible with data capture systems, enabling real-time analysis and insight into production line activity

- Tower lights can be installed as an option

- Solid state memory and ethernet connectivity

- Waterproof connectors

How it works

Cartons are formed then hot melt glue is applied to the carton flaps. The flaps are then folded and sealed to the carton sides to complete the assembly. By measuring that the glue is at the required temperature, has been applied to the correct area and in the desired quantity, you can be assured that the carton will not fail and is safe to be transported. Missing glue means potential breakages in logistics or at the point of sale. Badly shaped cartons means poor product sales.

The HotSpot vision system consists of a colour camera and FLIR LWIR camera, inspecting the areas where the flaps are sealed. The thermal imaging camera is providing a measurement of the glue temperature and location, through the carton material. The colour camera checks that the flaps have been properly formed and that the carton is of the correct shape. If HotSpot identifies a failure from either camera, the system can provide a digital output to the production line.